Technology

BMW Launches Sustainable iFactory in Debrecen, Hungary

The newly inaugurated BMW iFactory in Debrecen, Hungary, is setting a benchmark for sustainable automotive manufacturing. This cutting-edge facility, part of BMW’s global strategy, is designed to produce the all-electric iX3, which is expected to significantly reduce carbon emissions during its production.

Located on a 400-hectare site in Debrecen, this modern factory features 22 buildings and 14.9 kilometers of conveyor systems, with a logistics model that eliminates the need for external warehouses. Approximately 80% of the parts arrive directly at the assembly line, enhancing operational efficiency.

BMW aims to produce around 150,000 iX3 vehicles annually at the iFactory. It is staffed by about 2,000 employees, each equipped with smartphones that facilitate constant communication and quick problem-solving through the iFactory app. The factory has improved assembly line ergonomics by 30% compared to existing plants, making it a paperless environment where instructions are delivered via video screens at each workstation.

Innovative Energy Solutions

A distinctive feature of the BMW iFactory is its energy sourcing. The plant operates solely on electricity, making it the first mass-production automotive facility without any gas connection. Approximately 75% of its energy is derived from renewable sources, including hydro and wind, with the remaining 25% coming from an extensive solar array covering 500,000 square meters. This solar installation is the second largest in Hungary, with panels located on factory grounds and building rooftops.

The paint shop at the iFactory represents another world first, as it operates entirely without fossil fuels. Traditional paint shops typically use a mix of 44% oil or gas and 56% electricity. By leveraging advanced technologies such as power-to-heat systems and a unique thermal storage tank, the iFactory aims to reduce carbon dioxide emissions by up to 12,000 tonnes annually.

Battery Production and Future Models

The iX3 will feature BMW’s new Gen6 high-voltage battery technology, developed in collaboration with CATL and EVE Energy. The CATL facility, located just a short distance from the iFactory, is set to begin operations in early 2026, with an annual capacity of around 100 GWh. EVE Energy is also establishing a factory nearby, expected to produce 30 GWh annually by 2027. These developments will ensure a steady supply of battery cells for integration into the iX3 and future models.

Between now and 2027, BMW plans to launch 40 new or updated models that will utilize the innovative Neue Klasse technologies. The iFactory is expected to play a crucial role in this rollout, reflecting BMW’s commitment to sustainability and efficiency in vehicle production.

The visit to the BMW iFactory underscores a pivotal moment not just for the company but for the automotive industry as a whole. As traditional manufacturers grapple with challenges such as tariffs and competition in the electric vehicle market, the iFactory stands as a testament to the potential for sustainable and efficient vehicle production. BMW’s proactive approach to reducing its carbon footprint in manufacturing may well set a new standard for the industry moving forward.

-

World4 months ago

World4 months agoScientists Unearth Ancient Antarctic Ice to Unlock Climate Secrets

-

Entertainment4 months ago

Entertainment4 months agoTrump and McCormick to Announce $70 Billion Energy Investments

-

Lifestyle4 months ago

Lifestyle4 months agoTransLink Launches Food Truck Program to Boost Revenue in Vancouver

-

Science4 months ago

Science4 months agoFour Astronauts Return to Earth After International Space Station Mission

-

Technology2 months ago

Technology2 months agoApple Notes Enhances Functionality with Markdown Support in macOS 26

-

Top Stories3 weeks ago

Top Stories3 weeks agoUrgent Update: Fatal Crash on Highway 99 Claims Life of Pitt Meadows Man

-

Sports4 months ago

Sports4 months agoSearch Underway for Missing Hunter Amid Hokkaido Bear Emergency

-

Politics3 months ago

Politics3 months agoUkrainian Tennis Star Elina Svitolina Faces Death Threats Online

-

Politics4 months ago

Politics4 months agoCarney Engages First Nations Leaders at Development Law Summit

-

Technology4 months ago

Technology4 months agoFrosthaven Launches Early Access on July 31, 2025

-

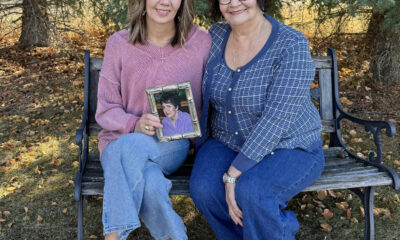

Top Stories2 weeks ago

Top Stories2 weeks agoFamily Remembers Beverley Rowbotham 25 Years After Murder

-

Top Stories5 days ago

Top Stories5 days agoBlake Snell’s Frustration Ignites Toronto Blue Jays Fan Fury