EDINBURGH, SCOTLAND – Researchers have unveiled a groundbreaking method to transform plastic waste into paracetamol using bacteria, signaling a potential revolution in sustainable drug production.

Immediate Impact

In a pioneering study, chemists have demonstrated that E. coli bacteria can be engineered to produce paracetamol, commonly known as acetaminophen, from plastic waste. This innovative process not only offers a more sustainable approach to drug manufacturing but also addresses the pressing issue of plastic pollution.

Key Details Emerge

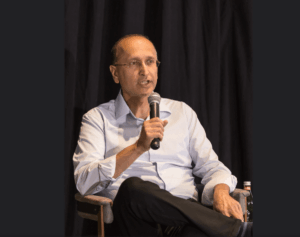

The study, led by Professor Stephen Wallace from the University of Edinburgh, reveals that paracetamol, a drug traditionally derived from oil, can now be synthesized using a byproduct of plastic bottles. “People don’t realize that paracetamol comes from oil currently,” Wallace remarked. “This technology shows that by merging chemistry and biology, we can make paracetamol more sustainably and clean up plastic waste at the same time.”

92% yield of paracetamol achieved in under 24 hours

Innovative Chemical Reactions

The research, published in Nature Chemistry, describes the discovery of a biocompatible chemical reaction known as a Lossen rearrangement. This reaction, previously unseen in nature, can occur in living cells without causing harm. The team achieved this by converting polyethylene terephthalate (PET), a common plastic, into a new material.

Industry Response

The announcement comes as industries seek more sustainable practices. The ability to convert plastic waste into valuable pharmaceuticals could significantly reduce environmental impact and reliance on fossil fuels.

“It is a way to just completely hoover up plastic waste,” said Wallace.

Genetic Engineering Breakthroughs

The researchers further engineered the E. coli bacteria by inserting genes from mushrooms and soil bacteria, enabling the conversion of PABA, an intermediary substance, into paracetamol. This process, which typically demands harsh laboratory conditions, occurred naturally within the bacteria, catalyzed by phosphate.

By the Numbers

- 24 hours – Time taken to convert PET to paracetamol

- 92% – Yield of paracetamol from the process

- Low emissions – Environmental impact of the process

What Comes Next

While further research is required to scale this method for commercial production, the potential applications are vast. This development builds on a growing trend of using biotechnology to address environmental challenges.

“It enables, for the first time, a pathway from plastic waste to paracetamol,” Wallace stated.

Background Context

The timing is particularly significant because of increasing global concerns over plastic pollution and the sustainability of pharmaceutical production. Traditional methods of producing paracetamol rely heavily on petrochemicals, contributing to environmental degradation.

Expert Analysis

According to experts, this breakthrough represents a significant shift from conventional drug manufacturing processes. By integrating biological systems with chemical engineering, the approach offers a dual benefit: reducing plastic waste and creating essential drugs more sustainably.

The move represents a significant shift from traditional practices, potentially setting a precedent for future biotechnological innovations in various industries.