World

Modern Turbofan Engines Thrive in Extreme High-Altitude Conditions

Commercial aviation is experiencing significant advancements in turbofan engine technology, designed to perform optimally at cruising altitudes of approximately 35,000 feet. These modern engines not only generate substantial thrust but also achieve remarkable fuel efficiency, particularly in the frigid, thin atmosphere at high altitudes, where temperatures can plummet to as low as -60 degrees Celsius. Despite these ideal conditions for performance, turbofan engines face unique challenges that require cutting-edge engineering and materials to ensure reliability and safety.

Challenges of High Altitude

The extreme conditions at cruising altitude present inherent risks for jet engines. Cold temperatures can cause materials to become brittle, leading to potential stress fractures. Additionally, high wind speeds and wind shear between 30,000 and 40,000 feet create forces that could compromise aircraft integrity without the advancements in modern engineering. One of the most perilous challenges is volcanic ash, which can severely damage engines by melting within the turbine. Rolls-Royce describes this threat by comparing it to “throwing a fist-sized ball of ice” into an engine at high speeds. Fortunately, thanks to exceptional engineering standards, the leading turbofan models have achieved a reliability rate of over 99% by 2025.

The latest turbofan engines are designed with a focus on high altitude efficiency, delivering both high thrust and low fuel consumption. The Brayton cycle is employed, which involves drawing in a large volume of air, compressing it through multiple stages, and mixing it with fuel in the combustion chamber. This process generates a high-energy gas flow that powers the aircraft. The air’s density at high altitudes complicates compression; however, the design of modern turbofans effectively addresses this challenge.

Advanced Technologies in Engine Design

Modern turbofan engines incorporate innovative technologies to mitigate the risks associated with extreme conditions. Variable geometry stator vanes help stabilize airflow, while Full Authority Digital Engine Control (FADEC) systems allow pilots to control throttle with precision. Advanced materials in the turbine’s hot section are engineered to withstand overheating caused by contaminants such as ash or ice.

Ice crystals pose a significant threat, as they can accumulate within the engine and lead to power loss. To combat this, hot air is diverted from the engine to critical areas to prevent ice formation. Rolls-Royce emphasizes that ice crystals can enter the engine while still frozen, subsequently melting and potentially causing blockages. Rigorous testing in specialized facilities such as the NASA Glenn Research Center ensures that engine designs can withstand these conditions.

Volcanic ash remains a serious concern due to its abrasive nature and the potential for silicates to melt and adhere to engine components. Advanced coatings and materials are employed to resist this damage, and ongoing research continues to improve engines’ resilience to such threats. The design of turbofans naturally directs larger ash particles away from the core, reducing the risk of damage.

To maintain operational safety, manufacturers like Rolls-Royce have implemented comprehensive monitoring and maintenance protocols. Data from FADEC systems are analyzed to identify any performance anomalies, guiding targeted maintenance actions. Routine inspections and thorough overhauls are conducted based on flight hours and cycles, ensuring engines remain in optimal condition.

The commercial aviation sector has seen notable leadership from manufacturers such as GE Aerospace, Pratt & Whitney, and CFM International. GE’s engines, including the GE90 and GE9X, have set benchmarks in thrust and efficiency. The GE90 was the first engine to exceed 100,000 pounds of thrust, while the GE9X holds the Guinness World Record for thrust at 134,300 pounds.

Pratt & Whitney’s innovative Geared Turbofan technology has transformed efficiency in modern aircraft, exemplified by the PW1000G engine used in the Airbus A320neo. CFM International leads the narrowbody engine market with its CFM56 and LEAP engines, designed for the Boeing 737 MAX and Airbus A320neo.

As the aviation industry continues to evolve, the shift from four-engine jets to twin-engine aircraft has prompted a focus on enhanced reliability and fuel efficiency. Regulatory changes, such as the Extended-range Twin-engine Operational Performance Standards (ETOPS), enable twin-engine aircraft to operate on longer routes, further emphasizing the need for dependable engine designs.

With advancements in monitoring systems and proactive maintenance strategies, the reliability of modern turbofans has significantly improved. The economic benefits of fewer engines have catalyzed innovations that prioritize lower maintenance costs and fuel consumption. As engine designs become increasingly sophisticated, the future of commercial aviation looks poised for continued growth and safety.

-

World4 months ago

World4 months agoScientists Unearth Ancient Antarctic Ice to Unlock Climate Secrets

-

Politics2 days ago

Politics2 days agoSecwepemc First Nation Seeks Aboriginal Title Over Kamloops Area

-

Entertainment4 months ago

Entertainment4 months agoTrump and McCormick to Announce $70 Billion Energy Investments

-

Lifestyle4 months ago

Lifestyle4 months agoTransLink Launches Food Truck Program to Boost Revenue in Vancouver

-

Science4 months ago

Science4 months agoFour Astronauts Return to Earth After International Space Station Mission

-

Technology2 months ago

Technology2 months agoApple Notes Enhances Functionality with Markdown Support in macOS 26

-

Top Stories4 weeks ago

Top Stories4 weeks agoUrgent Update: Fatal Crash on Highway 99 Claims Life of Pitt Meadows Man

-

Sports4 months ago

Sports4 months agoSearch Underway for Missing Hunter Amid Hokkaido Bear Emergency

-

Politics3 months ago

Politics3 months agoUkrainian Tennis Star Elina Svitolina Faces Death Threats Online

-

Politics4 months ago

Politics4 months agoCarney Engages First Nations Leaders at Development Law Summit

-

Technology4 months ago

Technology4 months agoFrosthaven Launches Early Access on July 31, 2025

-

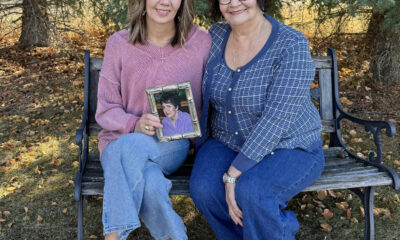

Top Stories2 weeks ago

Top Stories2 weeks agoFamily Remembers Beverley Rowbotham 25 Years After Murder